Computer-generated imagery (CGI) is amazing, but there’s no substitute for live filming. However, human-operated equipment can’t deliver the explosive speed and acceleration needed in today’s cutting-edge action films. When Mega Trax set out to build a robotic camera dolly that could travel at high speed and in harsh conditions, without compromising quality and reliability, it found that Elmo had the high-power servo drives they needed to make it happen.

Read this case study to learn how:

- Ultra-compact, highest-power servo drives enable high-speed, reliable action film shots

- Advanced tuning, filtering and scheduling options provide enhanced dynamic performance

- Elmo Application Studio EASII software tools make setup and tuning simple

- A Windows-based application enables users to quickly and simply configure the servo drive for their motor

Machine requirements

The Mega Trax design team faced significant challenges. Feature film cameras can weigh nearly 100 pounds and they travel along rails on a dolly that itself can weigh several hundred pounds. The motion needs to be fast, smooth, and repeatable so that the director can shoot the scene several times if needed.

In order to maintain motion quality, the team wanted to power each dolly wheel with a dedicated, high-power servo drive. The challenge was finding a solution that could deliver explosive acceleration while maintaining tightly synchronized operation among multiple drives to prevent shakiness in the shot. In addition, the solution needed to be portable, so the drives had to be compact, lightweight and efficient enough to enable a reasonable battery lifetime.

The solution also had to be easy to customize and learn. Filmmakers operate on tight budgets and even tighter shooting schedules — there’s no time to program the motion for each shot. Finally, the solution needed to be robust enough to survive the conditions of outdoor filming, including temperature extremes, dust and dirt, moisture, shock, vibration, and more.

The Elmo Motion control solution included:

- 4 Gold Drum HV servo drives

- Elmo Application Studio II (EASII) motion design software

The Mega Trax design team chose the Gold Drum HV servo drive from Elmo Motion Control to meet their complex needs, installing one drive to power each of the dolly’s four wheels. Each Gold Drum HV servo drive can handle up to 100A/800V and can deliver more than 65kW of continuous output.

It’s not just the quantity but the quality of motion that counts. The team used the Elmo drives’ built-in intelligence and connectivity to achieve highly synchronized operation of all four axes. The four drives are linked together in a master-slave architecture using EtherCAT/CANopen. Remote connectivity via a mobile device allowed Elmo technicians to optimize performance in real time by tuning the drives on the track.

Software

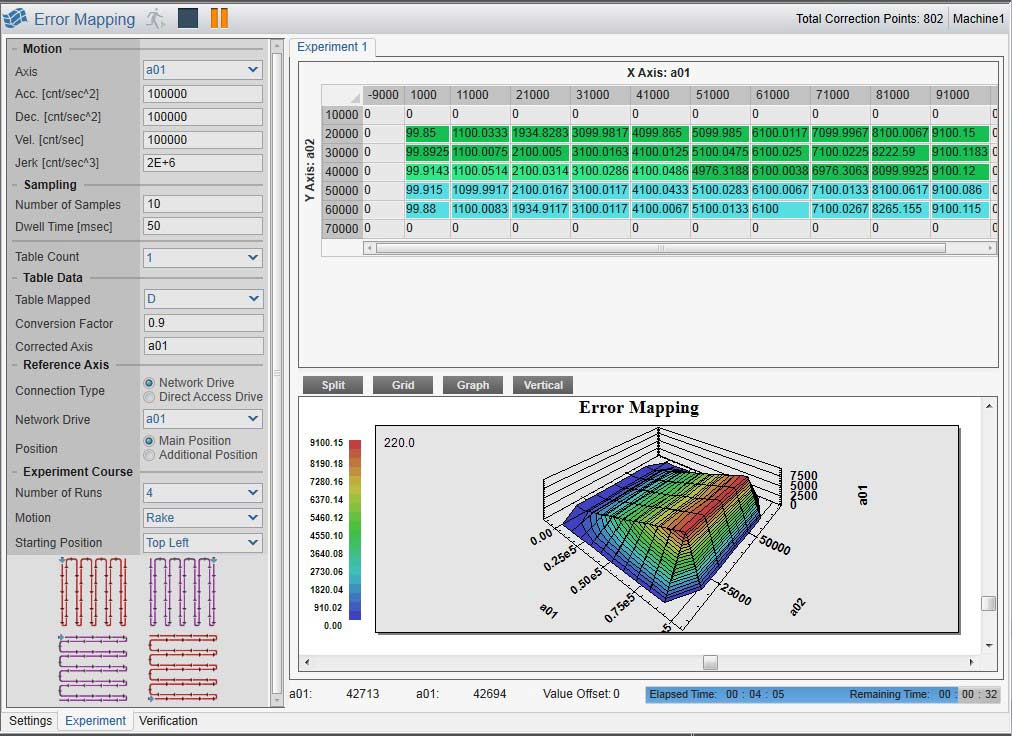

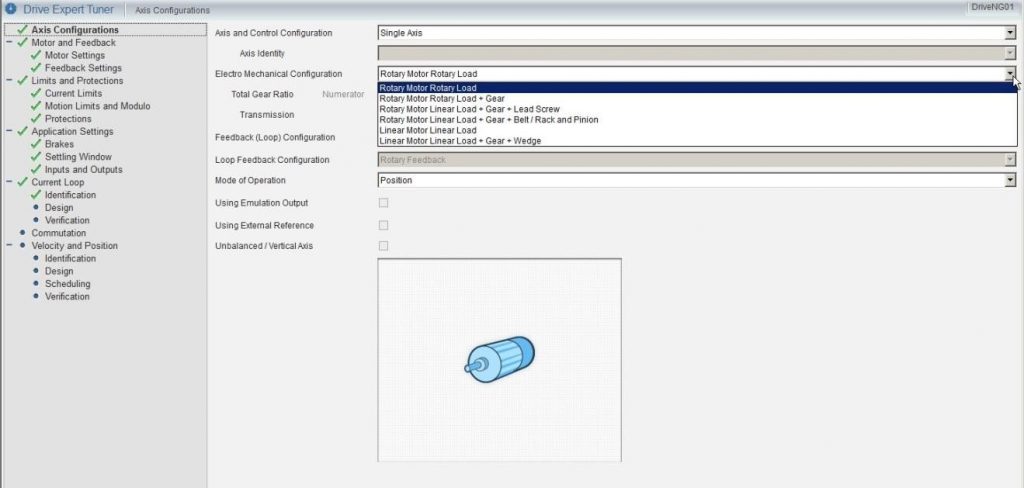

The Mega Trax team used Elmo Application Studio II (EASII) motion design software to create a flexible, user-friendly programming environment where users can create and implement motion, and intuitively program Elmo’s servo drives. “I loved the online tool that provides EASII software training with a live video link to a real machine—it allowed me to personally perform a quick tune on our motors to get everything rolling,” says David Kuklish, Co-founder and VFX Supervisor, Mega Trax. The EASII motion design software tool also provides accurate mechanical plant transfer functions; 1D, 2-D, and 3D error mapping and corrections; drive feedback emulation; and corrective servo tuning features.

The outcome

Using Elmo’s servo drives and software, Mega Trax developed the MX 500 semi-autonomous, high-speed robotic dolly system. The compact, high-power servo drives allow the MX 500 to accelerate cameras to speeds of >90 mph in seconds and operate over terrain with grades of up to 60%, executing moves repeatedly and reliably, even in rugged conditions. Gold Drum drives operate with efficiencies of up to 99% so the MX 500 can complete up to 50 high-speed, quarter-mile runs per battery charge. “Elmo has a great reputation for precision motion control, so we already had a high level of confidence in the company,” says Howard McCain, co-founder, and CEO of Mega Trax. “Then, we realized that Elmo’s drives were the only ones that could handle our power and motion control requirements.”

EASII

Elmo Application Studio II Software