Perfectly tuned servo axes and efficient EtherCAT networking enabled the rapid design of a fast, high-precision bottle labeling and capping machine.

Over 2 trillion drink containers are produced globally every year. The high-volume demand and small profit margins mean that manufacturers must be able to churn out bottles at a breakneck pace. Elmo worked with a labeling and capping machine manufacturer to build a solution that could label bottles faster and more efficiently, without compromising accuracy. Read the fully story.

Read this case study to learn about:

- The advantages of using Elmo Gold Duet (integrated motor and drive).

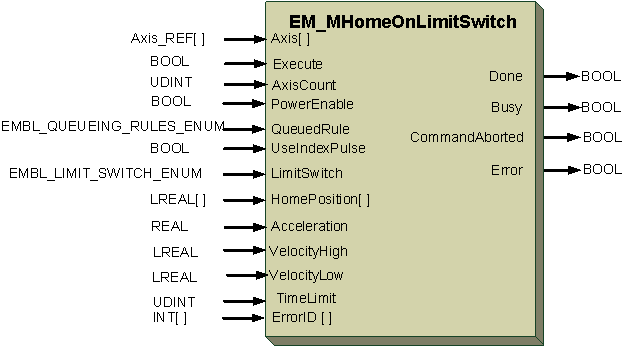

- What is EMBL (Elmo Advanced Motion Blocks) and how they shorten the development time.

- Why our Platinum Maestro is the best choice to implement the system motion control.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Background

Realization of a fast bottle labelling (or capping) machine challenges the design and execution of complex and dynamic motion profiles. In this application, bottles are automatically fed into machines and transferred to a rotating platform at line speeds of over 60,000 labels per hour. High-speed cameras take pictures of the bottles and transfer them to a host computer that processes the data and calculates the exact label position using an image processing algorithm.

Machine Requirements

The labeling and capping machine included more than 60 integrated motors on a rotating platform. The high-speed rotation, coupled with unfavorable conditions such as vibration, humidity and extreme temperatures, required a robust motion control solution that was also compact enough to be integrated into the motors and axes. To achieve the high speed without compromising precision, the company needed a tool that could provide complex control of rotating mechanics. It also had to transmit fast, deterministic and signal-integrity-sensitive EtherCAT communication via the slip ring media.

The company wanted to implement the motion control solution quickly, without needing external high-level engineering expertise.

Motion Control Solution

- Gold Whistle Miniature Servo Drive (1-20A/100VDC, 3-9A/200VDC)

- Gold Duet 40 Integrated Drives and Motors (100V – 200V, 400V)

- Maestro Multi-Axis Controller

- EASII: Elmo Application Studio II Software

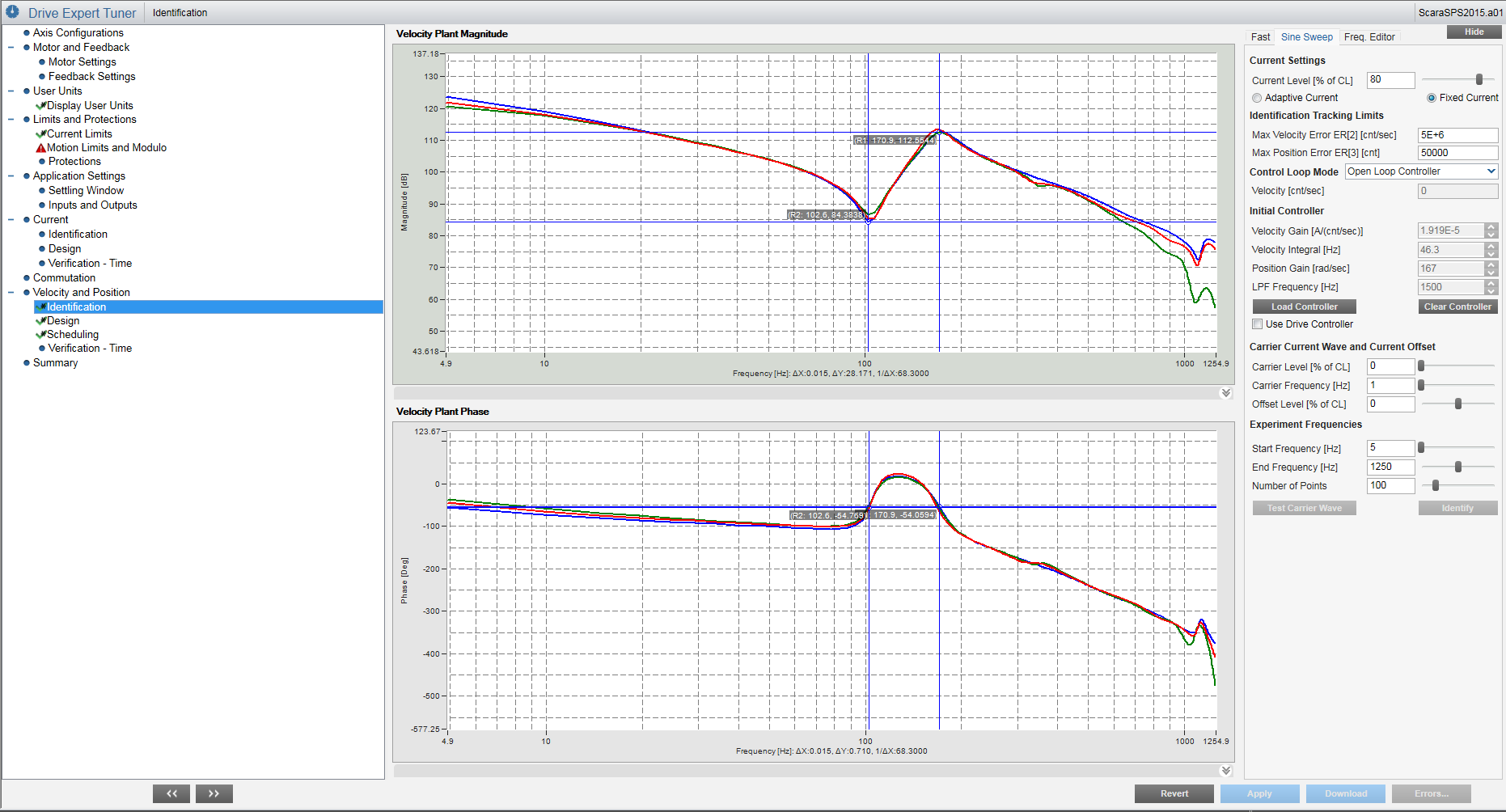

The team selected the powerful Gold Whistle servo drives for the motors, as they are compact, efficient, robust, and can be integrated into the motors. They simplify the rotating carousel, reduce space and weight, restrict the cabling to DC bus plus EtherCAT communication cables, and minimize the electrical cabinet. The Gold servo drive can also overcome the non-linearity of the mechanical load to achieve the widest bandwidth and fastest response. This enables fast, stable operation, high throughput, and error-free operation.

Gold Duet drives were chosen for the 60 axes that sit on the rotating platform. The tiny, small-footprint Duets utilize direct coupling to ensure precise rotation during camera image capturing. They are rugged enough to withstand the mechanical vibrations of the rotating platform and their minimum cabling enables low EMI and RFI.

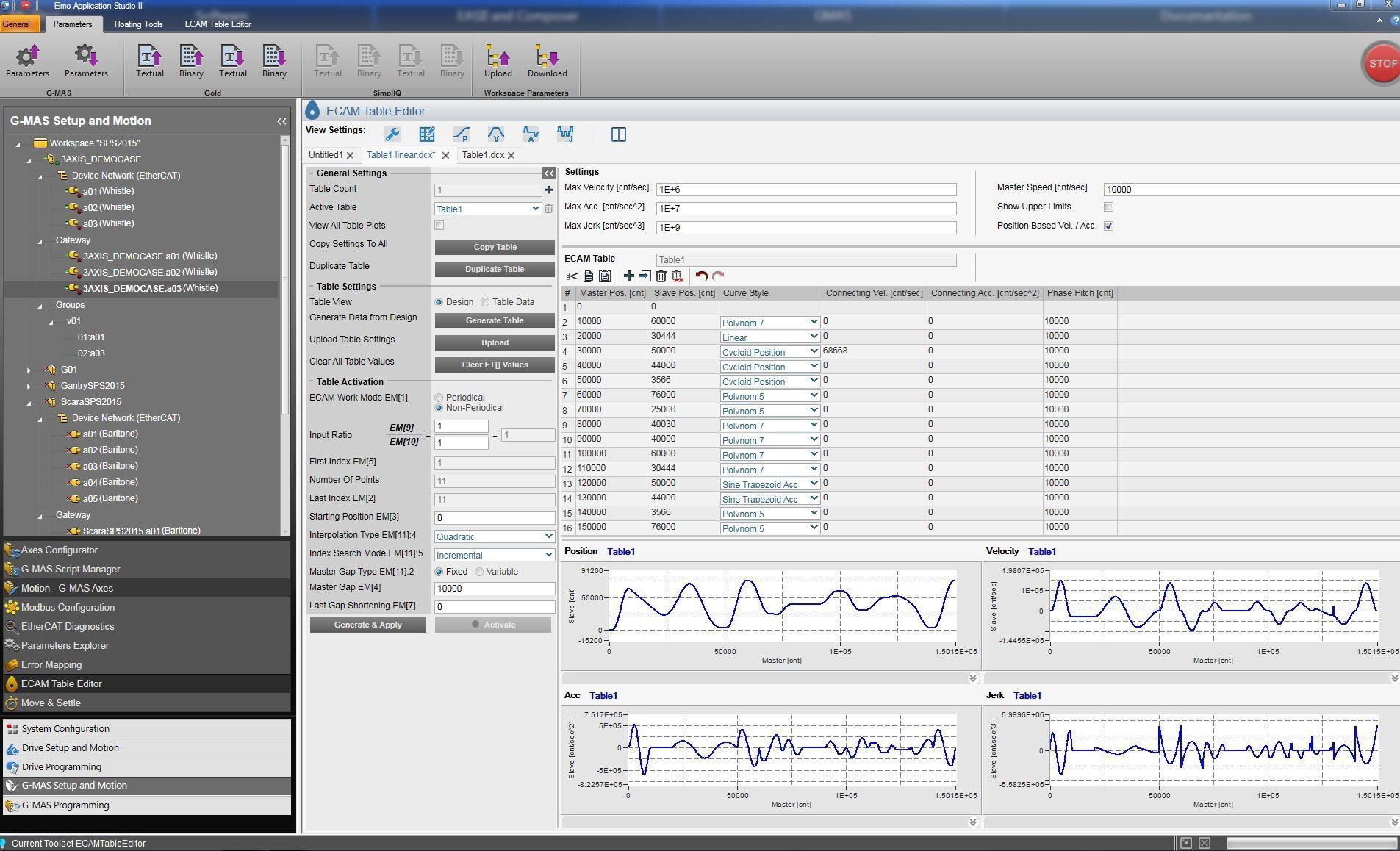

The drives are controlled by Elmo’s Maestro multi-axis controller, which sets the initial target labeling position. All slaves operate in DS-402 standardized cyclic synchronized position mode. The Maestro allows high interpolation levels for smooth motion trajectories with a minimum number of ECAM points. It enables fast dynamic table calculations, execution, table switching, multi-hierarchy topology building, virtual axes synchronization and related advanced features that simplify and accelerate the implementation process, while precisely executing the complex motion scenario.

Elmo Application Studio II Software (EASII), featuring advanced tools such as servo tuning, ECAM, error mapping and network configuration, simplified the motion development process. Other advanced Elmo tools, including Elmo Advanced Motion Blocks (EMBL) comprising sophisticated motion blocks, libraries, and machine templates, simplified programming in the process development stage. The two sets of tools together eliminated the need for multi-disciplinary implementers, saving engineering resource, while dramatically improving the motion control performance and reducing time to market. Elmo also developed numerous EMBLs that simplify the development process and continue to develop and introduce new EMBLs at no additional cost.

EASII

Elmo Application Studio II Software

Gold Duet 40

Integrated Drives and Motors

100V – 200V

Gold Maestro

Advanced Ethercat, Multi- Axis Motion Controller

Gold Whistle

Miniature Servo Drive

1-20A/100VDC, 3-9A/200VDC

The Auto Tuner resolves any mechanical drawback within few minutes

ECAM builder Tool in a matter of Minutes

Results

Elmo’s advanced motion control dramatically simplified and eased the implementation process to the level of ordinary engineering (no wizards). Instead of the several weeks typically required, Elmo’s solution shortened the motion control design and operation development to less than three days.