Beverage caps and labels may look simple, but nowadays, putting them on bottles involves some very advanced technology. When a bottling company updated its capping and labeling machine, it wanted to increase efficiency without making significant mechanical changes. Electronic CAMs with digital servo drives by Elmo proved the perfect solution.

Read this case study to learn about:

- Electronic cams with digital servo drives

- Achieving double throughput while minimizing changes to existing mechanical and electrical systems

- Improving efficiency in existing machines without making major mechanical changes

Background

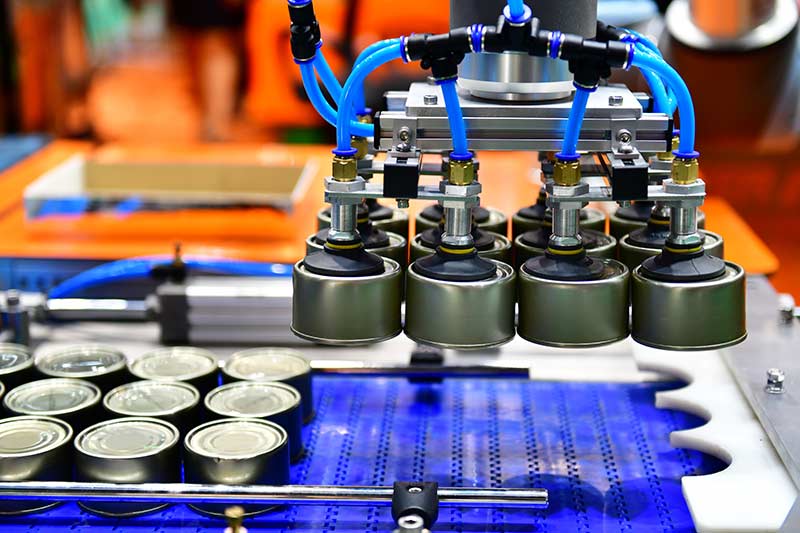

Rotary carousels are commonly used in labeling and capping machines. The rotary motion applied to the bottle holder platter or capping chuck regulates the tightening torque that is applied by a magnetic clutch. However, mechanical cam systems are often inefficient due to the mechanical couplings that require complex and costly installation procedures and ongoing maintenance. Additionally, they lack the needed format flexibility and have limited scalability, both during the design stage and for machines already in service.

The disadvantages of a mechanical CAM have to lead many companies to replace them with an electronic cam that drives each platter/chuck with an onboard electric motor. Electronic CAMs offer advantages in format flexibility, as the format is managed electronically and allows modifications to the machine operating cycle.

The Elmo Motion Control solution included:

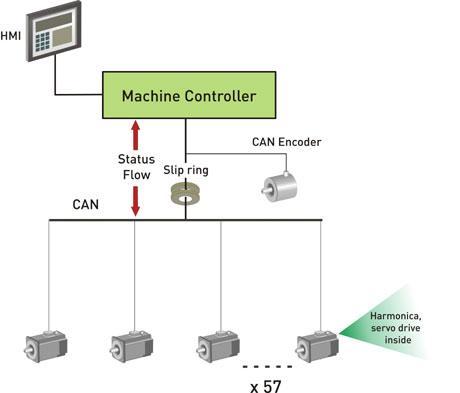

- 57 Elmo Harmonica servo drives

- Master Encoder Via CANopen network

The company chose the Harmonica servo drive operating in ECAM mode for its labeling and capping machine. The small size of the drive enables the engine to be placed inside the bottle axis without a timing belt and the drive robust enough to withstand the shock when the bottle is pressed.

The machine was assembled with two labeling systems, with the central controller identifying a label picture placed on the bottle after the first label. An ECAM table operates in each drive. All of the axes are slaves of the main axis in the carousel, with every axis beginning to move at a different location point of the master. The initial slave ECAM position is triggered by a vision camera through the central controller. The encoder sits in the static part of the machine and provides the location information of the carousel’s central axis using CANopen communication, without any additional wiring.

Advanced ECAM programming also significantly enhanced the machine’s flexibility. The bottle’s movement profile can be changed without making any mechanical changes to the machine. For example, the manufacturer can easily change the bottle turning speed based on the bottle’s radius.

The outcome

This Elmo solution significantly increased the machine’s update rate from 4 ms/point to 2 ms/point while reducing the network baud rate from 15 MHz to 500 KHz. Its distributed networking and advanced programming capabilities enabled the company to improve efficiency in existing machines without making major mechanical changes.

Today’s Solution:

Elmo has introduced new solutions and options since this machine was designed. Today:

- The system can be controlled and operated using Elmo’s Platinum Maestro (PMAS) or the PMAS-IO multi-axis motion controller, through a wireless network from a centralized PLC or computer.

- The application can use the Gold or Platinum servo drives.

- The system can be operated via a high-speed RT EtherCAT network.

Harmonica

Compact and Smart Digital Servo Drive

Up to 12A Up to 200V

Not Recommended for

New Designs

Platinum Maestro

High Precision Ethercat Muilti-Axis Motion Controller