Using Elmo’s Harmonica Digital Servo Drive, TekCel of Hopkinton, Massachusettes designed and built a very compact material handling system for test tubes and plates. The Harmonica was designed into an enclosure that operates at a study -20° C.

Background

Modern medical testing laboratories must automate their test procedures in order to lower costs and stay competitive. Drug and biotech companies do the same to speed up their product development cycles.

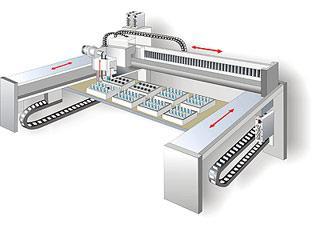

Automated material handling and storage systems, for medical laboratories, are now available to do just that. They contain trays for storing chemicals and test materials in inert, temperature-controlled environments, and handling systems for moving the trays to test areas where materials can be mixed automatically. The resulting mix is placed in test tubes or plates and are then either stored in the same system or transferred out of it.

At the heart of such systems is (1) a database that knows where the materials are stored and keeps a history of each individual test tube or plate, and (2) a computer that controls all activities and movements.

TekCel’s Tube Management Platform

TekCel’s Approach

TekCel’s approach is to build individual storage, transfer, and mixing modules that can be assembled and disassembled as easily as building blocks. Each storage module contains its own database so that the overall system, when assembled, knows what’s inside each and every tube or plate within the system.

TekCel’s Tube Management System is a fully automated, integrated and environmentally controlled platform for flexible format tube storage, retrieval and processing. The system provides unparalleled flexibility in tube format, storage capacity and throughput.

At the core of the Tube Management System is the TubeStore module. Each self-contained module is equipped to pick and compile individual 2-D barcoded tubes, or 96-tube racks, within an inert, temperature controlled environment. The modular design of the TubeStore allows the capacity of the Tube Management System to be expanded by combining multiple TubeStore modules.

The Challenge

Distribute motor controls in a limited amount of space and in a low temperature environment.

- tight space limitations

- provide power for linear and rotary motors

- control by self-contained programs (position mode)

- connectivity via CANopen

TekCel and Elmo’s Solution

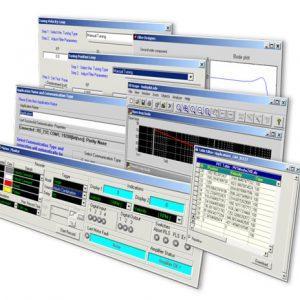

TekCel adopted a Windows PC-based control architecture, which offers many advantages, but lacks real-time control. Because Elmo’s Harmonica can execute an internal script, it can coordinate servo motors, sensors and pneumatics into an autonomous sequence of events. Multiple scripts can be retained in on-board fl ash memory and, after initiation, no further support is required from the PC.

Previously, sensors and servo positions were polled by the PC and servo/output commands issued. The embedded script eliminated delays due to latency and improved throughput by approximately 30%. In this application multiple Harmonica’s are configured as a “group” and their application-specific scripts initiated via a single PC command, enabling multiple servos to work together on real-time tasks.

Previously, TekCel utilized a proprietary distributed servo controller that utilized a multi-drop RS485 network. The Harmonica provided a similar package size with more current capability, more robust CAN communication, wide operating temperature range and similar cable management. Expanded I/O and advanced servo tuning were other factors that made the switch to the Harmonica the logical choice.

The Harmonica digital sevo drive was designed into two major components: the storage system and the plate management unit.

Harmonica Digital Servo Drive

The Harmonica is a fully digital servo drive that delivers up to 1 KW of continuous power (and 2 KW of peak power) for DC brush, brushless and linear motors. It can operate in current, velocity or position modes and functions with a wide variety of feedback options including Incremental Encoders, Resolvers, Interpolated Analog (Sine/ Cosine) Encoders, tachometers and potentiometers. The tiny drive packs one horsepower into a 150 gram (5.3 oz) package. It features sinusoidal vector control, trapezoidal vector control, trapezoidal six-step and DC commutation methods. The Harmonica has an auxiliary feedback port for ECAM, Follower, Dual Loop and Pulse-and-Direction applications. Digital and analog ports are also available. Integrated into the drive is highly efficient power switching technology aligned with Elmo’s especially fast implementation of CANopen networking (DS-301/DS-402) protocol. One CANopen port is installed along with one RS-232 serial port for communications. The Harmonica is fully programmable with Elmo Motion Control’s programming language (32 KB of memory is available for storing programs). Using Elmo’s Composer setup tool, Harmonica users can perform drive setup, configuration, tuning, analysis and drive programming quickly and easily.