Correct non-linear mechanical position errors on a multi-axis system

Used In:

- High-end application solutions

Used In:

The G-MAS correct mechanism axis positions based on preset data that is accessed using a user-defined correction table. Such corrections are possible for both single and multi-axis applications.

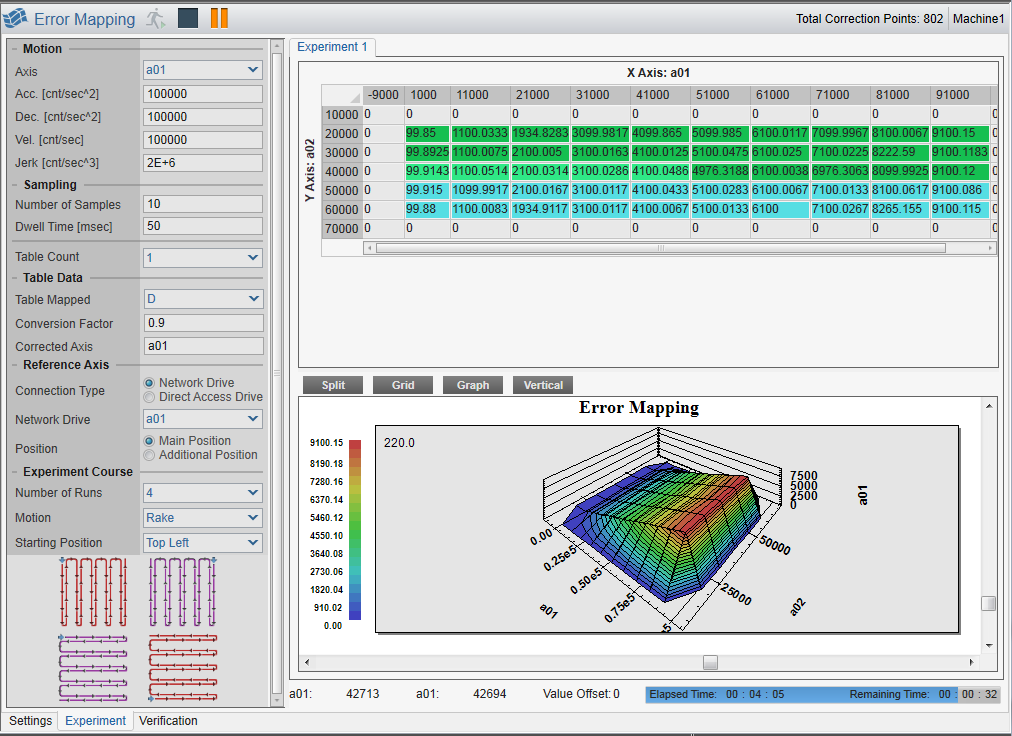

The EASII Error Correction dedicated tool allows an automatic measurement, implement and experiment of error correction tables for single and multi-axis high end solutions.

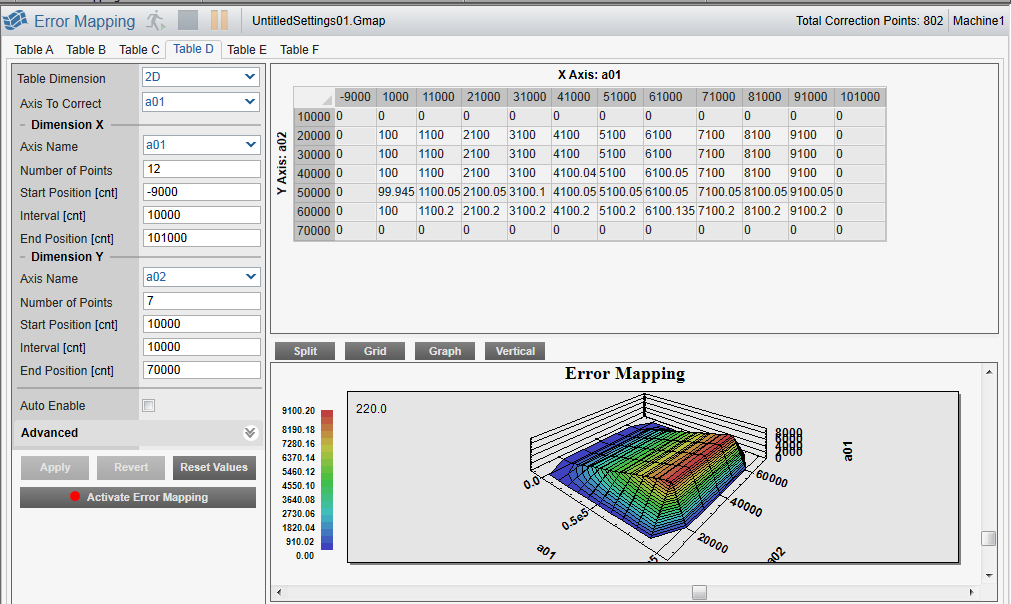

Both 2D and 3D corrections are supported:

G-MAS error correction supports up to 6 two-dimensional tables and up to 100,000 tabulated correction positions.

Correction points can be calculated automatically by the EASII application studio or pre-defined by the user during general setup.

Error Mapping EASII Tool – Settings

Error correction settings for the Drive and G-MAS:

Error Mapping – Experiment

EASII measures the error correction points and automatically generates a table:

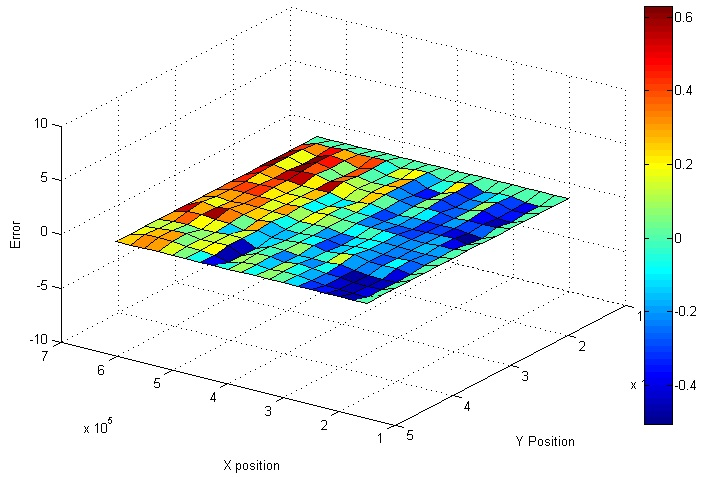

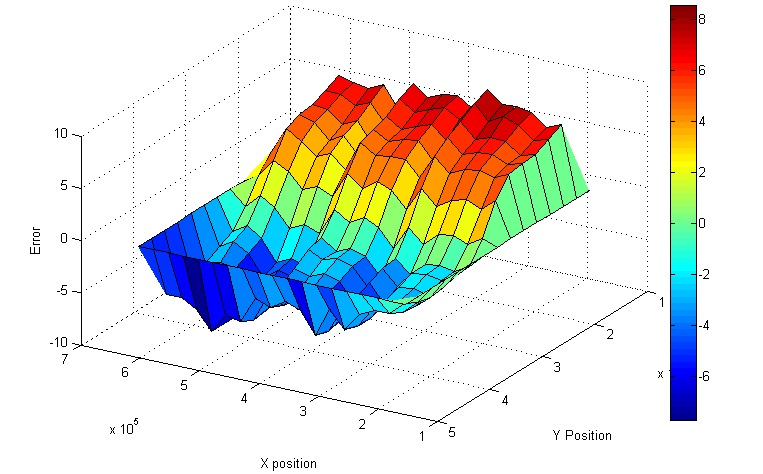

A Nano-metric system in micron units before and after Error Correction

Before:

After: